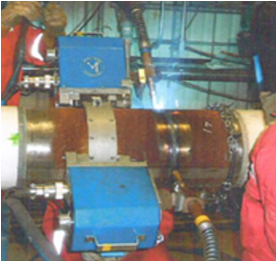

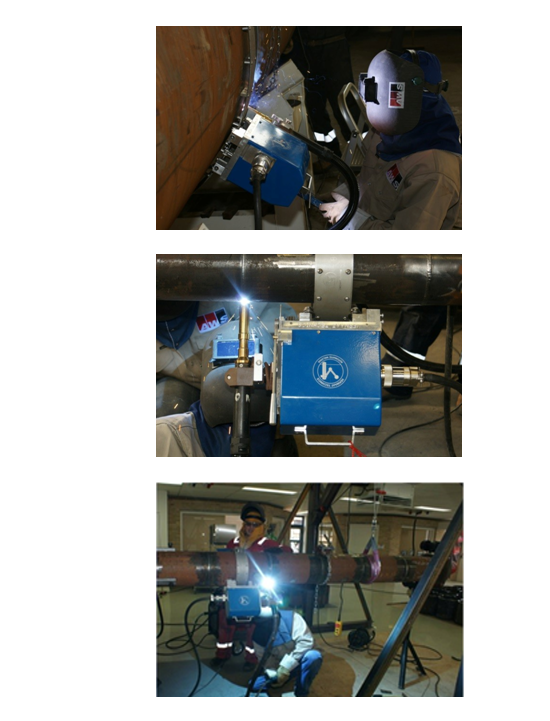

Providing Automatic Pipelines Welding Services

VCM Dewpoint Sdn Bhd (VCMD) provides specialist services for the oil and gas construction industry. It is currently providing services in automatic welding of offshore/onshore pipelines.

Read More

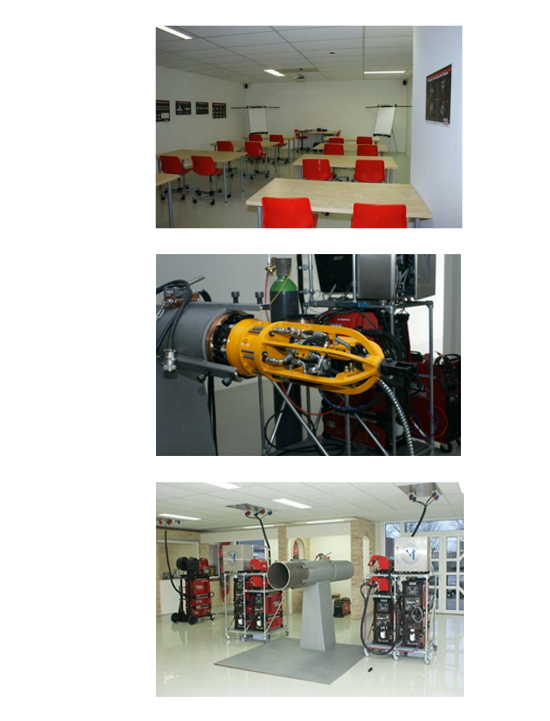

Focusing on Training & Development

VCMD focuses in the training and development of personnel, i.e. welding technician and supervisor. Our training centre located in Kota Bharu, Malaysia

Read More